We have BIS and NABL Accredited Electrical Safety Testing Electrical Safety Testing Laboratory. Mr.Puneet Sharma Call 08196980555 E-mail: Itcindiaone@gmail.com

Tuesday, 29 June 2021

Friday, 25 June 2021

Are You Looking For IP67 Testing and Certification on your Enclosure?

IP67 Testing and Certification for Enclosure

If Yes! Then You are at the Right Place, We can provide you IP67 Testing and certification for your Enclosure

What is IP67 testing?

IP originally established by the IEC International Electro-Technical Commission stands for International Protection Rating. The first digit indicates the protection level from solid objects or materials, the second indicates the Protection level from liquids and fluids (water). In this case, IP67 can totally protect against dust ingress. As for the ingress of liquids, IP67 can protect it for about 30 minutes.

How to Get IP67 Testing and Certification for Enclosure? IP 67 Testing Procedure

Here is the process of Getting IP67 Testing and Certification for Enclosure, We can do Enclosure IP67 Testing as per IEC EN 60529 Standard

Two types of IP67 Testing:

- IP67 Dustproof Testing and

- IP67 Rainproof/waterproof Testing

IP67 = IP (Ingress Protection) 6 dust-tight + 7 protection from liquids, immersable to specification

1st Digit- Protection Against Solid Ingress:

- > 50mm gap for entry

- > 12 mm gap for entry

- > 2.5 mm gap for entry

- 1.0 mm gap for entry

- Dust protected

- Dust-tight

2ndDigit- Protection Against Liquid Ingress:

- Vertically dripping water

- Dripping water tilted at 15 deg

- Spraying water at an angle up to 60 deg

- Splashing water in any direction

- Jets of water from any direction

- Heavy seas or powerful jets of water

- 6K Powerful water jets with increased pressure

- Harmful ingress of water when immersed between a depth of 150 to 1000 mm (5.9 - 40 in)

- Continuous immersion in water

- 9K Powerful high-temperature water jets 1

What are the Test Equipment’s Used for IP 67?

- Dust Chamber

- Motor Drive For Spray Apparatus

- Jet Test Set With Flowmeter

- Gauges And Test Probes

- Drip Box

- Water Supply Unit For Drip Box

- Turntable For Drip Box

- Tube For Spray Apparatus

- Motor Drive For Spray Apparatus

- Telescope Support

- Spray Nozzle

- Wall Electrolift For Drip Box

- Water Jet Hose Nozzle Dia

- Jet Test Set

- Tilted Support For Ipx2 Test

- Water Distiller

- Dynamometer

- Jointed Test Finger

If You Want to Purchase/Buy IP67 Testing equipment, We Can Provide you at a Reasonable Price

How Can IP67 Testing Improve Your Production Processes?

- Test for product quality and performance issues, which can help reduce warranty costs

- Introduce opportunities to improve product reliability while reducing liability

- Improve methods of producing more parts with less scrap, minimizing waste

- Verify process control validations through test results

What is the charge of IP67 Testing for Enclosure?

Answer: Charges Depend on Product Dimensions, Costing Start from 10000 to 1lakh

What Are the duration or Time Periods of IP67 Testing for Enclosure?

Answer: You will get a test report within a week

If You Want IP67 Testing And Certification For Your Products!

We have a testing facility of IP67 Testing and Certification to provide you an official quotation please share the Product's details like (dimensions + photo).

We are Providing Testing and Certification service all over India, Mumbai, Kolkata, Delhi, Chennai, Bangalore, Hyderabad, Pune, Ahmedabad, Surat, Visakhapatnam, Chandigarh, Ludhiana, Noida UP - 201304,

If you have any Requirements for testing on the product, please feel free to contact us.

Mr. Puneet Sharma

+91-8196980555 - 07986633030

Contact on Whatsapp https://wa.link/86ucwa

Email: ITCIndiaOne@Gmail.Com

People also ask:

- What is IP67 testing?

- Is IP66 better than IP67?

- What does IP67 waterproof mean?

- How is IP67 tested?

- How do I test IP67?

- What is IP67 certification?

- Can you shower with IP67??

People Searches Related :

- ip67 shower

- can ip67 be used for swimming

- ip66 vs ip67

- ip67 test procedure

- ip67 vs ipx7

- ip testing procedure

- ip testing equipment

- ip67 certification cost

- ip67 leak rate

- ip testing uk

- ip67 testing

- ip rating self-certification

Friday, 23 April 2021

Are You looking for a NABL BIS and Tec Approved Electrical Safety Testing Laboratory?

Electrical Safety Testing as per International/European Standard EN / BS EN / IEC / ISO / DIN

Are You looking for a NABL BIS and Tec Approved Electrical Safety Testing Laboratory?

NABL BIS TEC Approved Electrical Safety Testing Laboratory - EMC EMI testing - Electro-Medical Device Testing- Mechanical safety Testing

We are pleased to inform you that, we have ISO 17025:2017 NABL, BIS and Tec Accredited testing facility in India. In order, to enable global acceptance NABL, BIS and Tec maintains linkages with international bodies like International Laboratory Accreditation Co-operation ILAC and Asia Pacific Accreditation Co-operation APAC

We have testing facility for all types of Electro-Medical and Electro- Mechanical safety testing, e.g. IEC / EN 60601, ISO 80601 series, IEC / EN 60204, IEC / EN 61010, IEC / EN 60950, IEC / EN 60335, IEC / EN 61439 and etc.

People also ask about Electro-Medical Device Testing:

We can do electrical safety testing of Electro-Medical Device as per Popular standards IEC 60601-1, IS 13450, Medical Device Compliance Testing Services.

What is electrical safety testing of medical equipment?

The main purpose of performing an electrical safety test on medical equipment is to ensure patient safety. It is important to test equipment for any electrical internal breakdowns and leakage currents, as well as damage to power cords, AC main feeds, fuses, and power bars.

Is IEC 62353 mandatory?

IEC 62353 does not apply to manufacturers and cannot be referred to in medical device regulation.

What is medical device testing?

Medical device testing is a critical step in the process of transforming an innovative design into a reliable and marketable product. Our testing puts your product through a comprehensive medical devices industry assessment and helps you demonstrate compliance with standards and regulations around the world.

How do I sell my medical devices in Europe?

To sell medical devices in the EU European Union, you must obtain or apply for CE Marking Certification for your product. CE Mark indicates that your medical device complies with the applicable European Union regulations and enables the commercialization of your products in 32 European countries.

People searches Related Electro-Medical Device Testing:

- Safety testing of medical devices

- Introduction of electrical safety test

- Electrical safety testers medical equipment

- EBME electrical safety testing

- Electrical safety test equipment

- Importance of electrical safety testing

- Medical equipment safety ppt

- Electrical integrity testing

We are looking forward to having a discussion on this subject and help you to meet the product requirement as per standard criteria via, verification, testing, and thus complete compliance. We also cater our support services for EMI/EMC testing as per IEC 60601-1-2, IEC 61000, IEC 61326, etc standards.

People also ask about EMI EMC Testing:

A critical step to bringing a new product to market includes EMI and EMC testing. A summary, guide, or tutorial about the basics of EMI EMC testing, EMC compliance testing, and the EMC test equipment needed as well as EMC testing services and EMC test labs or EMC test houses.

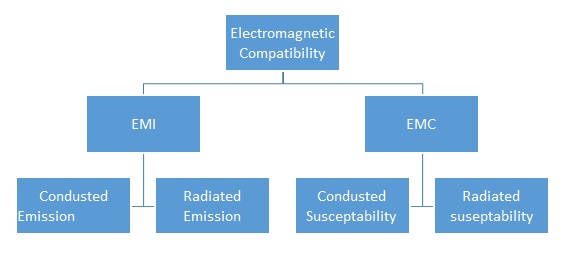

What is EMI EMC testing?

EMI/EMC testing is a critical step in bringing a new product to market. Emissions testing - measures the amount of electromagnetic noise generated by a device during normal operation. The purpose of these tests is to ensure that any emissions from the device is below the relevant limits defined for that type of device.

What is the difference between EMI and EMC testing?

EMI stands for electromagnetic interference and is an electronic emission that interferes with components, RF systems, and most electronic devices. The difference between EMI and EMC is that EMI is the term for radiation and EMC merely is the ability for a system to operate within the presence of radiation.

What is an EMC test?

EMC testing measures the ability of equipment or systems to function satisfactorily in their electromagnetic environment without introducing intolerable electromagnetic disturbance to anything in that environment.

What is meant by EMI and EMC?

EMC Electromagnetic compatibility and EMI electromagnetic interference are frequently referred to when discussing the regulatory testing and compliance of electronic and electrical products.

People search Related EMI EMC testing:

⦁ EMI/EMC testing tutorial

⦁ emi/emc testing procedure pdf

⦁ emi emc testing standards

⦁ emi/emc testing ppt

⦁ emi/emc testing equipment

⦁ emi/emc testing for automotive

⦁ emi/emc testing labs in India

⦁ EMI and EMC pdf

People also ask about Machinery Safety tests:

We are Offering machine safety assessment, testing, and certification by industry standards ISO 13849 and IEC 61508

What should you check for before starting machinery?

Make sure the equipment is properly grounded before use. Check that keys and adjusting wrenches are removed from the machine before turning on the power. Inspect stock for nails, staples, loose knots or other defects before cutting, planning, routing or carrying out similar activities.

How do you perform a risk assessment machine?

Machine Safeguarding: Risk Assessment and Risk Reduction

Here is the Step by step Process:

⦁ Identify Machine/Process.

⦁ Engineering Controls

⦁ Collect Proper Information.

⦁ Awareness Means

⦁ Gather Proper Individuals.

⦁ Create an Appropriate Risk Reduction System

⦁ Administrative Controls

⦁ Observe Machine in Use.

⦁ Personal Protective Equipment

⦁ Hazard Elimination or Substitution

⦁ Accurately Estimate System Costs

⦁ Identify Hazardous Areas.

⦁ Provide All Required Services and Materials

⦁ Identify the Risk Level.

⦁ Conduct Follow-Up Risk Assessment

⦁ Evaluate the Risk Level.

⦁ Process Close-Out and Sign-Off

What are machine hazards?

A machine hazard occurs at the point of operation where the actual work is performed and can be created by components that transmit energy, such as pulleys, belts, chains, gears, couplings, or flywheels or. other parts which move while the machine is working, including reciprocating, rotating, and transverse parts.

Why is machinery safety important?

Moving machinery can cause injuries in many ways: Sharp edges can cause cuts and severing injuries, sharp-pointed parts can cause stabbing or puncture the skin, and rough surface parts can cause friction or abrasion.

People also ask about mechanical testing:

Mechanical safety Testing- Involves an evaluation and testing of a product's shape and design, and whether sharp edges or points can result in user injury

What are the mechanical testing methods?

We provide a variety of destructive testing methods all over India.

1. Impact Testing

2. Fatigue Testing

3. Tensile Testing

4. Fracture Toughness Testing

5. Stress Rupture Testing

6. Shear testing

7. Hardness Testing Laboratories

8. Fastener Testing

9. Residual Stress Measurement

What is mechanical safety?

Mechanical safety testing is a specific type of safety evaluation that involves the assessment of the mechanical aspects of a product, and the conditions under which a mechanical failure could pose a potential safety risk to users.

What is the purpose of mechanical testing?

Mechanical testing or engineering tests are performed to determine various mechanical properties of materials such as strength, hardness, ductility, toughness, brittleness, etc. There are several types of tests to determine various mechanical and physical properties of the material.

What is a mechanical stress test?

These tests test the impact of external stress on component joints and repeated use of the product over its service life cycle.

If you have any Requirements for testing on the product, Please feel free to contact us.Mr. Puneet Sharma+91-8196980555 - 07986633030

Email: ITCIndiaOne@Gmail.Com

Friday, 16 April 2021

Are you looking for IP55 Testing and Certification Electrical Panel?

Are you looking for IP55 Testing and Certification Electrical Panel?

If you are an Electrical Panel Manufacturer and looking for

IP55 Testing and Certification for your Electrical Panel, then you are at the

right place, we can provide you IP Testing and Certification service. We have

BIS, NABL, and Tec Approved Laboratory; we can do testing as per your Requirements.

How to Get IP55 Testing and Certification for Electrical Panel?

Here is the process of Getting IP55 Testing and

Certification for Electrical Panel. We can do Electrical Panel IP55 Testing as

per IEC EN 60529 Standard

Two types of IP55 Testing:

- IP55 Dust proof Testing and

- IP55 Rainproof/waterproof Testing

Test method for IP55 Dust proof Testing:

Electrical Panel tested in a dust chamber, in which talcum

powder is maintained in suspension by an air current. The chamber shall contain

2 kg of powder for every cubic meter of its volume. The talcum powder used

shall be able to pass through a square-meshed sieve whose nominal wire diameter

is 50 u m and whose nominal free distance between wires is 75 u m. It shall not

have been used for more than 10 tests.

Test method for IP55 RainProof/Waterproof Testing:

- Test for second characteristic numeral 5 with the 6,3mm nozzle.

- The test is made by spraying the enclosure from all practicable direction with a stream of water from a standard the nozzle as show in Figure 6.

The conditions to be observed are as follows: -

- The internal diameter of the nozzle 6,3mm

- Delivery rate: 12,51/min±5%

- Water pressure: to be adjusted to achieve the specified delivery rated

- Core of the substantial stream circle of approximately 40mm diameter at 2,5m distance from nozzle

- Test duration per square meter of enclosure surface area likely to be sprayed: 1 min

- Minimum test duration 3minuts

- Distance from nozzle to enclosure surface between 2,5m and 3m.

What is the charge of IP55 Testing for Electrical Panel?

·

Charges depend on product dimensions, Costing Start from 10000 to 1lakh

What are the duration or Time periods of IP55 Testing for Electrical Panel?

· You will get a test report within a week

What is the Test Equipment’s used for IP 55?

- The instrument used for IP Dustproof Testing: Sand and dust test chamber

- The instrument used for IP Waterproof /Rainproof Testing: Rain test chamber

If you want to Purchase/Buy IP55 Testing equipment, Please feel free to contact us

We have a testing facility of IP55 Testing and Certification to provide you an official quotation please share Product's details like (dimensions + photo).

We are Providing Testing and Certification service all over India, Mumbai, Kolkata, Delhi, Chennai, Bangalore, Hyderabad, Pune, Ahmedabad, Surat, Visakhapatnam, Chandigarh, Ludhiana, Noida UP - 201304,If you have any Requirements for testing (IP rating, IK rating) on the product Please feel free to contact us.

Mr. Puneet Sharma

+91-8196980555 - 07986633030

Contact on Whatsapp https://wa.link/86ucwa

Email: ITCIndiaOne@Gmail.Com

People S earches Related:

- IP Testing for Electrical Panel

- IP55 Validation Test Report

- ip55 Testing charge

- ip55 Testing duretion

- ip55 waterproof meaning

- ip55 rating table

- ip55 rating chart

- ip55 testing equipment

- Ingress Protection Test IP55

- IP5x

- IPx5

- IEC EN 60529

- ip55 testing procedure

- ip55 testing standards

Thursday, 15 April 2021

IP66 , IP67 , IK10 Testing on Indoor and Outdoor Cameras

IP66 , IP67 , IK10 Testing on Indoor and Outdoor Cameras -NABL, BIS, TEC Approved Labs -ISO/IEC/BS/EN Standards

Are you looking for IP66, IP67, IK10 Testing and Certification for Indoor and Outdoor Cameras, if yes, then you are at the right place, We will provide you testing and Certification service.

What is the IP66 Rating Testing?

IP66 Rating and Testing are dust-tight and provide a strong level of indoor-outdoor protection. Products that qualify for this rating will prevent ingress of water directed at high pressure. Typically, IP66 waterproof enclosures are used in washdown and outdoor applications, such as factories, rooftops, solar installations, and agricultural settings. They give maximum protection against pressure-washing and weather short of water immersion.

What is the IP66 Rating Testing and Certification?

- IP Rating: IP66 Enclosures

- Protection: Able to protect against powerful water jets

- Description: Water projected in powerful jets (12.5 mm nozzle) against the enclosure from any direction shall have no harmful effects.

What is the Test Method of IP66 Rating Testing and Certification?

- Test duration: at least 3 minutes

- Water volume: 100 liters per minute

- Pressure: 100 kPa at a distance of 3 m

What is the IP67 Rating Testing?

IP67 enclosures protect electronics against dust and moisture, including temporary immersion Use an IP67 rated enclosure when you want to be extra sure that your design will be protected from washdown and weather. Products that meet these ratings will protect electronics from blown dust and water ingress in aggressive weather, and they will even protect during total immersion in water to a depth of 1 meter for up to 30 minutes. Usually, immersion is not a regular feature of IP67 applications, but the rating gives added assurance of protection for critical electronic designs.

What is the IP67 Rating Testing and Certification?

IP67 Rating: IP67 Enclosures

Protection: Able to protect against Immersion up to 1 m

Description: Ingress of water in harmful quantity shall not be possible when the enclosure is immersed in water under defined conditions of pressure and time (up to 1 m of submersion).

What is the Test Method of IP67 Rating Testing and Certification?

- Test duration: 30 minutes

- Ingress of water in harmful quantity shall not be possible when the enclosure is immersed in water under defined conditions of pressure and time (up to 1 m of submersion).

What is the IK10 Rating Testing and Certification?

- IK10: Protected against 20 joules impact

- Equivalent to impact of 5kg mass dropped from 400mm above-impacted surface.

We are Providing Testing and Certification service all over India, Mumbai, Kolkata, Delhi, Chennai, Bangalore, Hyderabad, Pune, Ahmedabad, Surat, Visakhapatnam, Chandigarh, Ludhiana, Noida UP - 201304,

If you have any Requirements for testing (IP rating, IK rating) on the product Please feel free to contact us.

Mr. Puneet Sharma

08196980555 - 07986633030

Contact on Whatsapp https://wa.link/86ucwa

Email: ITCIndiaOne@Gmail.Com

https://lm-79-testing.blogspot.com/ https://electricalsafetytestinglab.wordpress.com/

People Searching:

- Indoor camera testing,

- Outdoor camera testing,

- IP Ratings,

- IP Testing lab,

- IP66 Testing,

- IP67 Testing,

- IK Testing,

- IP66 Waterproof Camera Testing,

- NABL Approved Lab,

- BIS Approved Lab,

- TEC Approved Lab,

- Ingress protection Testing,

- Waterproof Testing,

- Dust proof Testing,

- IP Testing Procedure for Camera,

Friday, 21 February 2020

Cables EMC Electromagnetic Compatibility Testing Labs

|

| Cables EMC Electromagnetic Compatibility Testing Labs |

Are You looking for Cables EMC Electromagnetic Compatibility Testing labs in India?

Advanced Cables EMC Testing Laboratory

Know the testing Fees against standard IEC/ IS for Cables - Email Now! ITCIndiaOne@Gmail.Com

The electromagnetic compatibility (EMC) principle of cables is that communication signals should be kept inside the cables, and outside electromagnetic fields should not disturb the data transmission inside the cable.

The requirement for COAXIAL Cables designed for Broadcast and communication Technology to avoid interference problem

| Sr. No | Metrics | |

| 1 | Impedance | Less than 5 mΩ/m from 5 to 30 MHZ |

| 2 | Screening Attenuation | 85 dB from 30 - 1000MHZ( Screening Class A , in IEC 61196-6 ) |

Majority of Coaxial cables available in the market do not full fill the above said the requirement that lead to EMC and Mechanical weakness. Thus, affects the immunity of the equipment.

Why choose ITCIndia For Cables EMC Testing?

If Your Buyers Demanding for Cables EMC Testing.– Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr Puneet Sharma | Call: 08196980555 | E-mail: ITCIndiaOne@Gmail.Com

Get Instant Quotations, Fill the Enquiry form:

Thursday, 5 December 2019

Solar Fence Energizer Testing Laboratories

|

| Solar Fence Energizer Testing Laboratories |

Advanced Electric Fence Energizer Testing Laboratory

Know the testing Fees against standard IEC 60335-2-79/ IS 302-2-76 for Electric Fence Energizer - Email Now! ITCIndiaOne@Gmail.Com

Why choose ITCIndia For Electric Fence Energizer Testing?

ITCIndia is a leading provider of comprehensive testing services for electrical and LED lighting products. Our global network of technical experts, combined with our state of the art testing laboratories, assure a single-source solution for meeting all applicable requirements, standards and voluntary schemes. And ITCIndia technical professionals are actively involved in international advisory boards and standards development activities, ensuring the most up to date knowledge of current and changing requirements.

Represented in over 5 locations in India, ITCIndia has an unsurpassed track record of meeting and exceeding the requirements and expectations of our client companies. The ITCIndia brand and our distinctive blue octagon mark are instantly recognized around the globe as symbols of quality and safety Testing and will increase customer confidence in your brand.

ITCIndia can assist companies in low-cost life testing and evaluating of their products for pre-compliance and compliance testing to schemes such as The Carbon Trust Enhanced Carbon Allowance

If Your Buyers Demanding for Electric Fence Energizer Testing.– Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr Puneet Sharma | Call: 08196980555 | E-mail: ITCIndiaOne@Gmail.Com

Get Instant Quotations, Fill the Enquiry form:

Tuesday, 3 December 2019

Photometry Testing Laboratory

|

| Photometry Testing Laboratory |

Are You Looking for Photometric Testing in India?

We validate your LED lighting competence parameters and reveal how your Photometric products perform in real life. With our precision instruments, ITCIndia can determine all photometric parameters. We always keep our lab up to date with the latest technological developments and standards. ITCIndia quality management ensures the highest degree of accuracy and reproducibility in operation.

Why choose ITCIndia For photometry Testing?

If Your Buyers Demanding for photometry Testing.

– Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr Puneet Sharma | Call: 08196980555 | E-mail: ITCIndiaOne@Gmail.Com

Get Instant Quotations, Fill the Enquiry form:

Searches related to Photometric Testing Lab:

- photometric testing definition

- photometry blood test

- photometric measurement

- lighting flux testing frequency

- lighting flux testing frequency

- lm 79 standard pdf

- lm82 test report

- led driver testing method

- led street light test report

- lm 79 test report sample

- photometric testing labs

- photometric testing definition

- photometry blood test

- photometric test for led light

- photometric measurement equipment

- ITCIndia lab testing

- Advanced Photometric Testing Lab

Thursday, 28 November 2019

IS 302 Electrical Safety Test Labs

Are You Looking for Hydraulic Baling Machine testing as Per IS 302 in India?

If you are looking for a Hydraulic Baling Machine Testing according to IS 302 Standards in India, ITC India Can Help You! ITC India one of the best IS 302 Testing Service Providers in India. ITCIndia Can do Hydraulic Baling Machine Testing as per IEC, EN, ISO, BIS StandardWhy choose ITCIndia For IS 302 Testing?

If Your Buyers Demanding for ELECTRICAL SAFETY AS PER IS 302.

– Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr Puneet Sharma | Call: 08196980555 | E-mail: ITCIndiaOne@Gmail.Com

Get Instant Quotations, Fill the Enquiry form:

Saturday, 12 October 2019

CISPR 11-EN 55011 - EMC EMI Testing labs

|

| CISPR 11-EN 55011 - EMC EMI Testing labs |

EMC EMI - EN 55011 - CISPR 11 Testing for Medical Devices

CISPR 11/ EN 55011

Amendment 2

Industrial, scientific and medical (ISM) radio-frequency equipment – Electromagnetic disturbance characteristics – Limits and methods of measurementCISPR 11 is a broadly used international standard for electromagnetic compatibility within Europe for electromagnetic emissions or disturbances from Industrial, Scientific, and Medical, ISM, Equipment. CISPR 11 is conserved by CISPR: the International Special Committee on Radio Interference. It has grown from a simple document to a complex document involving a number of types of products

CISPR 11 applies to a very huge variety of equipment including everything from Wi-Fi systems, microwaves through to arc welders, all of which fall into the industrial, scientific and medical category which can use the ISM license-free bands like 2.4 GHz.

CISPR 11, EN 55011 is a standard covering radiated and conducted emissions. Most products will require an assessment of immunity standards, such as EN 61326-1: Electrical equipment for measurement, control and laboratory use; or EN 61000-6-2: Generic Standards Immunity for industrial environments.

It has grown from measuring products at a larger distance (100 meters and 30 meters) for Class A Equipment to measuring them at 3 meters. Class B equipment measurement distances have seen an equivalent degradation of “far-field” radiated emission measurements. This steady erosion of the “laws of physics” is worrisome and a trend to reverse this erosion is overdue in the engineering field of EMC and the EMC Standards arena.

List of tests

Emission Tests | |

| CISPR 11 | Radiated emissions |

| Conducted emissions input power | |

| IEC 61000-3-2 | Harmonic current emissions |

| IEC 61000-3-3 | Voltage fluctuation & flicker |

Immunity Tests | |

| IEC 61000-4-2 | Electrostatic discharge immunity test |

| IEC 61000-4-3 | Radiated, radio-frequency, electromagnetic field immunity test |

| IEC 61000-4-4 | Immunity to Electrical Fast Transient |

| IEC 61000-4-5 | Immunity to Surges |

| IEC 61000-4-6 | Immunity to Conducted Disturbances |

| IEC 61000-4-8 | Power frequency magnetic immunity test |

| IEC 61000-4-9 | Pulse magnetic field immunity test |

| IEC 61000-4-11 | Voltage dips |

| IEC 61000-4-11 | Voltage interruptions |

If Your Buyers Demanding for CISPR 11 Testing – Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr. Puneet Sharma | Call: 08196980555 | E-mail: ITCIndiaOne@Gmail.Com

Get Instant Quotations, Fill the Enquiry form:

Thursday, 10 October 2019

CISPR 32-EN 55032 - EMC Testing labs

|

| CISPR 32-EN 55032 - EMC Testing labs |

CISPR 32/ EN 55032

Two classes of End-User Terminal Equipment Under Test EUT (Class A and Class B) are considered.

The aims of the standard are:

- To establish requirements which provide an adequate level of protection of the radio spectrum allowing radio services to operate as intended in the frequency range 9 kHz to 400 GHz;

- To specify procedures to ensure the reproducibility of measurement and the repeatability of results.

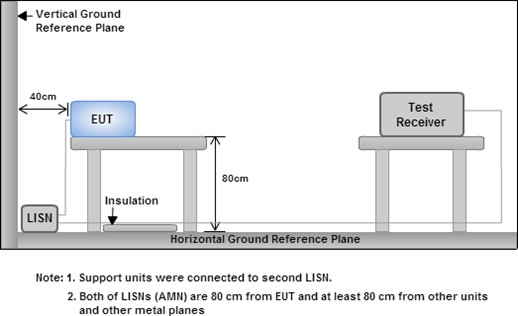

Conducted Emissions from the AC mains power ports

Test set up

Radiated Emission- Test set up

Radiated Emissions below 1 GHz

Radiated Emissions above 1 GHz

If Your Buyers Demanding for CISPR 32 Testing – Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr Puneet Sharma | Call: 08196980555 | E-mail: ITCIndiaOne@Gmail.Com

Get Instant Quotations, Fill the Enquiry form:

Sunday, 8 September 2019

CISPR 15 - EMC Testing labs

CISPR 15

CISPR 15ITC India is having best CISPR 15 Testing Labs to test LED. We provide all types of testing related to CISPR. Call at 08196980555 for CISPR 15 Testing Laboratories.

CISPR 15

LIMITS AND METHODS OF MEASUREMENT OF RADIO DISTURBANCE CHARACTERISTICS OF ELECTRICAL LIGHTING AND SIMILAR EQUIPMENT

Reference standards for Immunity test in CISPR 15

| S. N | Tests | Standard | Title |

| 1 | Electrostatic Disruption This test simulates electrostatic events and evaluates the ability of the EUT to tolerate such events. Testing is performed in accordance with IEC/EN 61000-4-2. All accessible enclosure surfaces and ports are evaluated unless specified as a static-sensitive surface. | IEC 61000-4-2: 2008 ESD Immunity | Electromagnetic Compatibility—Testing and measurement techniques - Electrostatic discharge immunity test |

| 2 | Electromagnetic Susceptibility The Electromagnetic Susceptibility test exposes the equipment under test to a calibrated uniform field of radiated electromagnetic energy. The EUT is continuously monitored while exposed to the required frequency range and field strength. The test chamber, radiating antennas, and calibrated fields meet the requirements of referenced standards | IEC 61000-4-3: 1996 Radio Frequency Immunity | Electromagnetic Compatibility—Testing and measurement techniques - Radiated radiofrequency electromagnetic field immunity test |

| 3 | Electrical Fast Transient This test injects a transient/burst interference onto the Mains input power supply and signal I/O lines. The EUT and peripherals are placed on a non-conductive support platform, 10cm above the test ground plane. The EUT is monitored for disturbances during the required exposure time of positive and negative bursts | IEC 61000-4-4: 1995-01 Electrical Fast Transient Immunity | Electromagnetic Compatibility—Testing and measurement techniques - Electrical fast transient/burst immunity |

| 4 | Lighting Surge This test simulates a lightning event by inducing transients onto the AC/DC power supply lines in common and differential mode. Testing is performed in accordance with IEC/EN 61000-4-5. The product-specific standard determines the minimum requirement for the exposure to surge transient levels | IEC 61000-4-5: 1995-02 Surge Immunity | Electromagnetic Compatibility—Testing and measurement techniques - Surge immunity test |

| 5 | Conducted RF Immunity This test injects a disturbance directly onto AC/DC power. Testing is performed in accordance with IEC/EN 61000-4-6. The product-specific standard sets the level, duration, and the frequency range to apply. | IEC 61000-4-6: 1996-04 RF Common Mode Immunity | Electromagnetic Compatibility—Testing and measurement techniques - Immunity to conducted disturbances, induced by radio-frequency fields |

| 6 | Power Disturbance This test subjects the EUT to power network faults and “brownouts”. Testing is performed in accordance with IEC/EN 61000-4-11. The EUT is powered up to a nominal voltage, and then software controlled voltage dips and interruptions are introduced | IEC61000-4-11: 1994-06 Voltage Dips and Short Interruptions | Electromagnetic Compatibility—Testing and measurement techniques - Voltage dips, short interruptions and voltage variations immunity tests |

- Criterion A - The equipment shall continue to operate as intended without operator intervention. No degradation of performance or loss of function is allowed below a performance level specified by the manufacturer when the equipment is used as intended. The performance level may be replaced by a permissible loss of performance. If the minimum performance level or the permissible performance loss is not specified by the manufacturer, then either of these may be derived from the product description and documentation, and by what the user may reasonably expect from the equipment if used as intended.

- Criterion B - During the test, the degradation of performance is allowed. However, no change in the operating state or stored data is allowed to persist after the test. After the test, the equipment shall continue to operate as intended without operator intervention. The performance level may be replaced by a permissible loss of performance. If the manufacturer does not specify the minimum performance level (or the permissible performance loss), then either of these may be derived from the product description and documentation, or by what the user may reasonably expect from the equipment if used as intended.

- Criterion C - Loss of function is allowed, provided the function is self-recoverable or can be restored by the operation of the controls by the user in accordance with the manufacturer’s instructions. Functions, and/or information stored in non-volatile memory, or protected by a battery backup, shall not be lost. For each test method, the test standard specifies the appropriate criterion to be met.

This test measures the levels emanating from the EUT into the AC Mains, evaluating the potential for the EUT to cause radio frequency interference to other electronic devices. The EUT is configured based upon the requirements of the applicable test standard.

RADIATED EMISSION

This test measures the levels emanating from the EUT, thus evaluating the potential for the EUT to cause radio frequency interference to other electronic devices. Measurement methods are used in accordance with the test standard(s) referenced. The antenna is positioned at several heights while the EUT is rotated 360°. At each antenna height, the receiver scans and records the maximum peak emissions. From the recorded scans, a list of discrete frequencies is developed for that antenna polarity. The antenna is then rotated in polarity and the scan repeated. For each discrete frequency, the turntable is rotated to the determined worst angle and the receive antenna is varied in height from one to four meters for the final maximum emissions. For EUT’s with auto-ranging power supplies, a pre-scan evaluation may be performed to determine “worst-case” radiated emissions.

If Your Buyers Demanding for CISPR 15 Testing – Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr Puneet Sharma | Call: 08196980555 | E-mail: ITCIndiaOne@Gmail.Com

CISPR 22 - EN 55022 EMC Testing

CISPR 22 (An EMC standard for Information Technology (IT) Equipment)

| CISPR 22 CLASS A CONDUCTED EMI LIMIT | |||

| Frequency of Emission(MHz) | Conducted Limit (DBMV) | ||

| Quasi Peak | Average | ||

| 0.15 - 0.50 | 79 | 66 | |

| 0.50-30.00 | 73 | 60 | |

| CISPR 22 CLASS B CONDUCTED EMI LIMIT | |||

| Frequency of Emission(MHz) | Conducted Limit (DBMV) | ||

| 0.15-0.50 | 66 to 56 | 56 to 46 | |

| 0.50-5.00 | 56 | 46 | |

| 5.00- 30.00 | 60 | 50 | |

| CISPR 22 CLASS A 10-METRE RADIATED EMI LIMIT | |||

| Frequency of Emission(MHz) | Field strength limit(DBMV/M) | ||

| 30- 88 | 39 | ||

| 88-216 | 43.5 | ||

| 216-960 | 46.5 | ||

| Above 960 | 49.5 | ||

| CISPR 22 CLASS B 3-METRE RADIATED EMI LIMIT | |||

| Frequency of Emission(MHz) | Field strength limit(DBMV/M) | ||

| 31- 88 | 40 | ||

| 88-216 | 43.5 | ||

| 216-960 | 46.0 | ||

| Above 960 | 54.0 | ||

If Your Buyers Demanding for CISPR 22 Testing – Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr. Puneet Sharma | Call: 08196980555 | E-mail: ITCIndiaOne@Gmail.Com

Friday, 9 August 2019

Are You Looking for BIS Approved Labs for LED Testing?

|

| BIS Approved Labs for LED Testing |

Are You Looking for BIS Approved Labs for LED Testing?

We are providing LED Lights Testing and Certification as Per BIS Standards in Mohali, Chandigarh, Mumbai, Chennai, Ahmedabad, New Delhi, Ahmedabad, Pune, Kolkata, Bangalore, India

Are You Looking for led lighting standards testing and certification in India?

Our products have been placed under special Testing and certification schemes check below:

LED testing As per IS 15885 (PART-2/SEC-13):2012

This includes insulation resistance, electric strength, creepage distances, and clearance between primary and secondary circuits, along with:

- SELV Safety Extra Low Voltage control gears

- Auto wound control gear

- Protection against electric shock

- Isolating control gears

- Separating control gears

LED testing As per IS 10322 (PART 5/SEC-1): 2012

We Can Do LED testing as per INDIAN STANDARDS, Hare you can see a list of the Following Indian LED Testing Standards:

- 16101: 2012 General Lighting - LEDs and LED modules – Terms and Definitions

- 16102(Part 1): 2012 Self- Ballasted LED Lamps for General Lighting ServicesPart 1 Safety Requirements

- 16102(Part 2): 2012 Self-Ballasted LED Lamps for General Lighting ServicesPart 2 Performance Requirements

- 16103(Part 1): 2012 Led Modules for General LightingPart 1Safety Requirements

- 16103(Part 2): 2012 Led Modules for General LightingPart 2 Performance Requirements

- 15885(Part2/Sec13): 2012 Safety of Lamp Control Gear Part 2 Particular Requirements Section 13 d.c. or a.c. Supplied Electronic Controlgear for Led Modules

- 16104 : 2012 c. or a.c. Supplied Electronic Control Gear for LEDModules - Performance Requirements

- 16105: 2012 Method of Measurement of Lumen Maintenance of solid State Light (LED) Sources

- 16106: 2012 Method of Electrical and Photometric Measurements of Solid-State Lighting (LED) Products

- 16107Part 1):2012 Luminaires PerformancePart 1 General Requirements

- 16107-1:2012 Luminaires Performance Part 2 Particular RequirementsSection 1 LED Luminaire

- 16108: 2012 Photobiological Safety of Lamps and Lamp Systems

Testing Advantage From us as per BIS STANDARDS :

Why Choose Us For BIS Testing?

If Your Buyers Demanding for LED Testing as Per BIS – Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2